SETCON® Flagship Project in Germany

SETCON variable speed gearbox has been successfully running at the power plant Mittelsbüren in Bremen, Germany operated by swb Erzeugung AG. As the retrofit project, SETCON gearbox provided energy savings of app. 12 800 MWh per year.

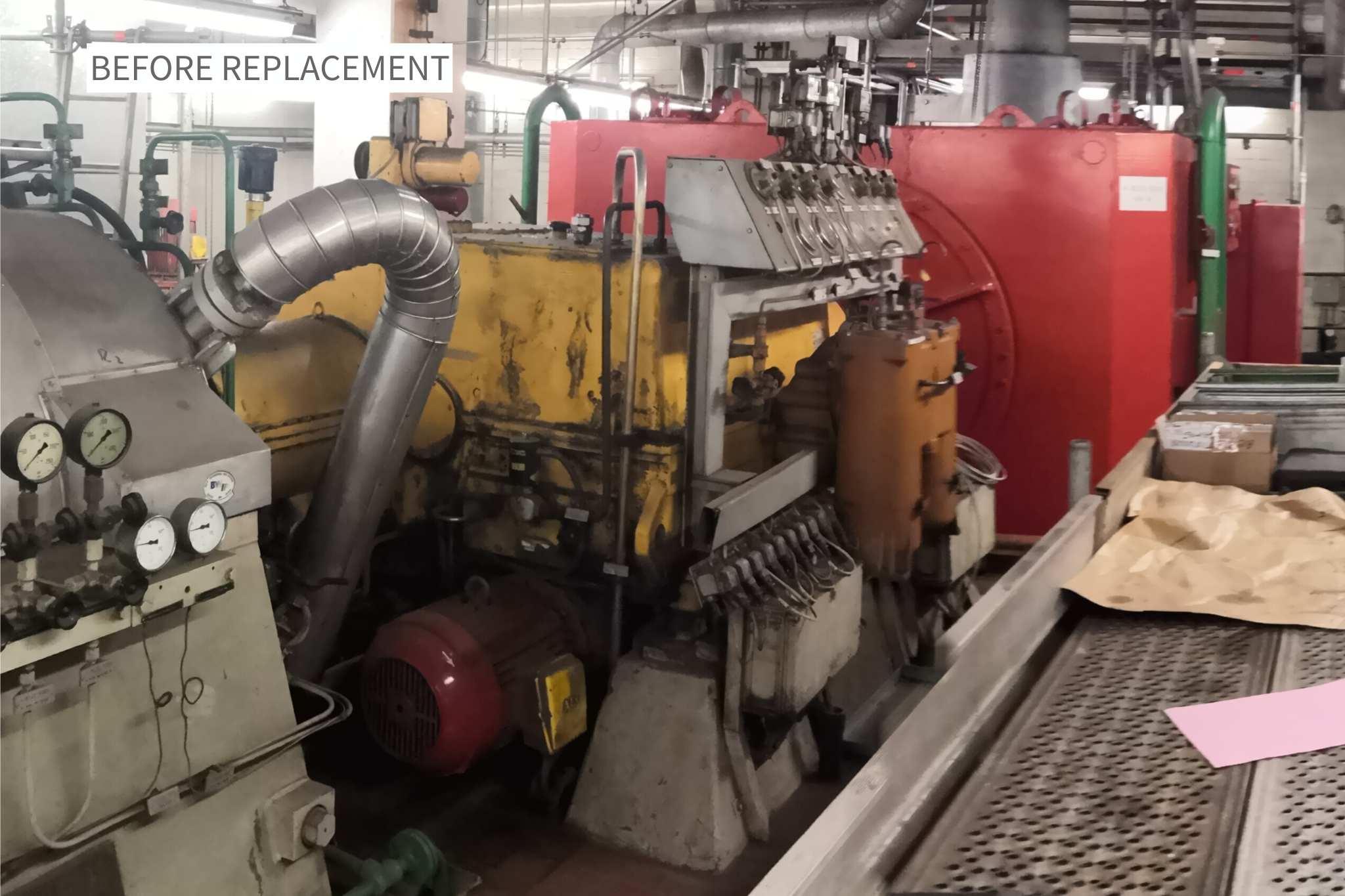

SETCON SE6 replaced the existing 6.5 MW Voith R 18 K 600 hydro-dynamic gear coupling in order to master future challenges in terms of CO2 reduction, energy efficiency, and reliability. SET's drive has emerged as the most superior technology in comparison to the competition owing to its customized design, compact packaging size, and robust low-voltage electronics. SETCON matching footprint allowed to maintain the existing infrastructure of the power plan and install the SE6 model within only 14 days.

Discover the remarkable advantages of replacing the R 18 K 600 hydro-dynamic gear coupling with the SETCON electro-mechanical variable speed gearbox. This innovative solution brings:

• Significant energy savings: approximately 12,800 MWh per year, equivalent to the annual consumption of ~4,250 German households,

• CO2 emissions reduction: cutting 12,400 tons of greenhouse gas emissions per year,

• Removal of hydro-dynamic gear coupling,

• Fast installation and commissioning: mechanical and electrical implementation of SETCON gearbox completed in 15 days,

• Foundation reuse: existing anchor points of the R 18 K 600 were exploited, with no need for foundation changes,

• Fast installation and commissioning: mechanical and electrical implementation of SETCON gearbox completed in 15 days,

• Foundation reuse: existing anchor points of the R 18 K 600 were exploited, with no need for foundation changes,

• SETCON footprint optimized to existing systems: constant-speed Main Motor and Booster pump were reused without modifications. Neither the BFP nor the Main Motor had to be repositioned on the existing foundation,

• Enhanced cooling efficiency: the existing lube oil cooler remained operational, while the working oil cooler was shut down due to lower losses and reduced oil demand of the SETCON gearbox,

• Enhanced cooling efficiency: the existing lube oil cooler remained operational, while the working oil cooler was shut down due to lower losses and reduced oil demand of the SETCON gearbox,

• Low-voltage electrical components, including Frequency Converters and Control Cabinet, designed for maximum immunity and robust performance,

• Simple and safe integration into the existing control system (through the SET control system simulation and customer acceptance tests at the advanced SET Test Bench).

• Simple and safe integration into the existing control system (through the SET control system simulation and customer acceptance tests at the advanced SET Test Bench).