,,Δ p” presents the DSgear-set® in its latests Online Journal

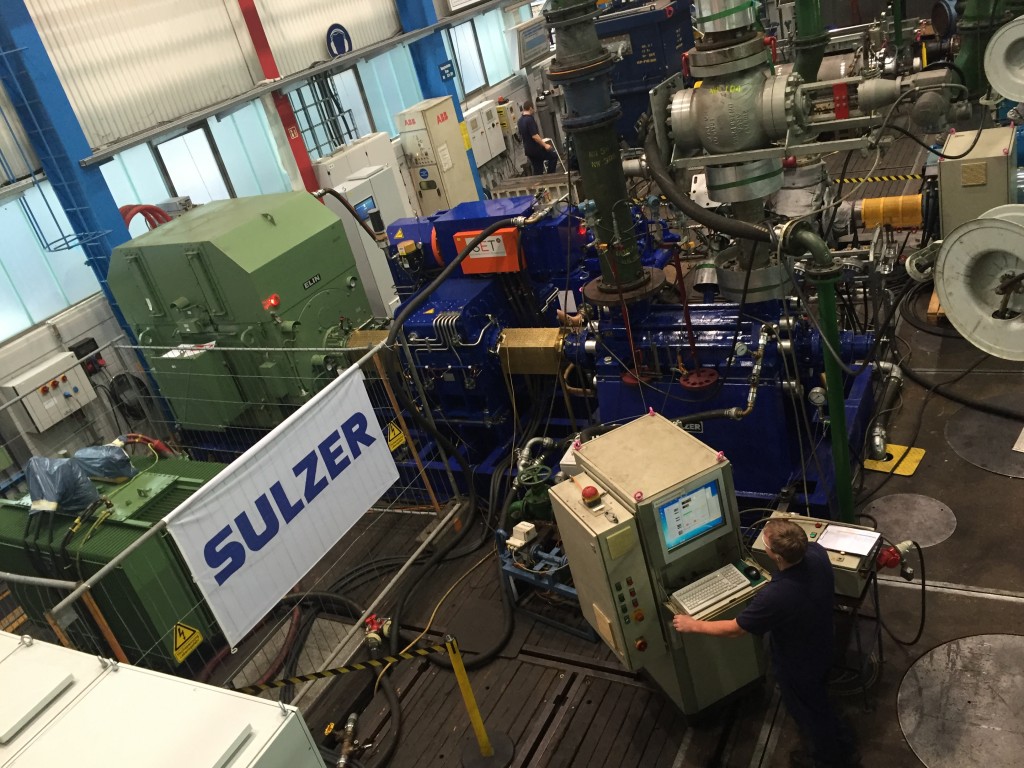

In the Online-Journal of the renowned Pump-Magazine ,,Δ p” the flagship project in cooperation with Sulzer (Deutschland) Pumpen GmbH at the PCK Raffinerie in Schwedt, Germany is presented. More information will come shortly in the next Print-Journal of ,,Δ p”.

“Sulzer: Völlig neuartige Drehzahlregulierung für Kesselspeise-Pumpen” [only in German language availiable]

Rüdiger Nagel 25.11.2015…Sulzer erhielt Ende 2014 einen Retrofit-Auftrag zu einer bestehenden Sulzer Kesselspeisewasserpumpe. Die bisherigen Betriebsdaten dieser Pumpe, die im Kraftwerk der PCK Raffinerie Schwedt/Oder betrieben wird. […der ganze Artikel]